FMG

Гарантійний та післягарантійний сервіс.

Офіційний представник

2025 модельний ряд

FMG (Farm Machinery Group) is a Finnish company specializing in machinery for agriculture, forestry, and the municipal sector. Its products are known for their durability, efficiency, and adaptability, making the company one of the leaders in the Northern European market. Here is a brief history and key advantages of the FMG brand:

History of FMG

FMG was founded in Finland to develop and manufacture high-quality machinery capable of operating in the challenging climatic conditions of Northern Europe. Addressing the needs of local farmers, forestry companies, and municipal services, FMG focused on designing reliable equipment that can function in various environments, from snowy streets to marshlands and dense forests.

Through continuous development and the implementation of new technologies, FMG has expanded its product range to meet demands not only in the domestic market but also across Europe and beyond. Today, the brand is associated with high-quality machinery that helps businesses and organizations maintain stable operations in any conditions.

FMG Brand Advantages

Durability and Longevity

- FMG machinery is designed to operate in extreme conditions common in Northern Europe, such as low temperatures, heavy snow, marshy soils, and dense forests. Built with robust materials and reliable structures, FMG products withstand heavy loads and extended working hours

Technological Innovation

- The company actively incorporates modern technologies into its products, ensuring high performance and efficiency. FMG uses advanced developments to guarantee operational safety and optimize energy consumption, making its machinery costeffective for businesses.

Adaptability and Versatility

- FMG products feature a wide range of applications. From snow-clearing equipment to forestry machinery, the company offers solutions that can be easily adapted to specific customer needs. This ensures flexibility and multifunctionality of FMG machinery.

Environmental Responsibility and Sustainability

- FMG aims to minimize the environmental impact of its products. Their equipment is designed to reduce emissions and fuel consumption while maintaining high efficiency, meeting modern standards of environmental responsibility.

Support and Service

- FMG provides a high level of customer support, including technical assistance, maintenance, and spare parts supply. This allows customers to rely on uninterrupted operation of the machinery for many years.

The FMG brand combines Finnish engineering craftsmanship with innovation, offering reliable solutions for various industries. Their machinery enables companies and organizations to work efficiently even in the most challenging conditions, ensuring stability and high-quality performance.

The FMG bucket sweeper has been designed as a multi-purpose sweeping machine. In addition to standard road and street sweeping, the bucket sweeper is excellent for quickly cleaning large indoor areas such as shopping-mall garages. The bucket can be used to collect large objects first, followed by final cleaning with the sweeper. FMG bucket sweeping machines can also be equipped with a separate container and a washer, similar to open-type sweepers. In the working position, the bucket floats on the rear rubber wheels and the front steel blade.

FMG bucket sweepers are available with a side brush unit on one or both sides. The side sweeper features a frame with hydraulic drive and suspension, allowing precise sweeping close to curbs. The side sweepers can be mechanically rotated into forward- or backward-sweeping positions, offering multiple sweeping options. Each side sweeper provides an additional 0.5 m of working width, and the side sweepers can be used either together or independently. The side-sweeper package can also be installed on existing bucket sweeping machines.

Model | Width, cm | Height, cm | Working width, cm | Water tank, L | Brush diameter, cm | Weight, kg | Bucket volume, L |

KH160Light | 180 | 108 | 160 | x | 70 | 440 | 470 / 260 |

KH160 | 180 | 108 | 160 | 150 | 70 | 520 | 845 / 460 |

KH200 | 220 | 108 | 200 | 150 | 70 | 730 | 1100 / 600 |

KH240 | 260 | 108 | 240 | 150 | 70 | 815 | 1300 / 740 |

KH260 | 280 | 108 | 260 | 150 | 70 | 860 | 1460 / 800 |

FMG open-type street sweepers are designed for cleaning both large and small areas and roads. Open sweeping machines are multifunctional equipment that can be used with a tractor to clean sand, dust, snow, and leaves. The main brush has a hydraulic drive that allows it to rotate 28 degrees in both directions.

Open sweepers float freely both in the direction of travel and sideways. Shock absorbers ensure smooth sweeping and excellent cleaning results.

Open sweepers require a minimum hydraulic flow of 50 L/min.

FMG open-type street sweepers can be equipped with a separate container and a washer (1000 L). The brush is mounted on a 3-point linkage and operates with a pressure of 200 bar.

Model | Width, cm | Height, cm | Working width, cm | Brush diameter, cm | Weight, kg | Min. pump capacity, L/min |

AH200 | 225 | 110 | 200 | 70 | 420 | 55 |

AH240 | 265 | 110 | 240 | 70 | 440 | 55 |

AH260 | 285 | 110 | 260 | 70 | 460 | 55 |

AH300 | 330 | 110 | 300 | 90 | 590 | 70 |

The FMG sweeping machine is designed for cleaning asphalt roads and areas. Additional side brushes provide excellent results when cleaning along curbs and walls.

The sweeping machine can be attached to front loaders of tractors and wheel loaders. The pressure of the main brush can be easily adjusted manually or hydraulically. Thanks to this adjustment, the machine follows the surface very well, and the cleaning quality is excellent.

Additional equipment for collecting debris in sweeping machines includes an electric valve, a sprinkler system, and side brushes with hydraulic lifting, lifting the debris container even from both sides.

| Model | Working width of the main brush, cm | Working width of the side brush, cm | Water tank, L | Trash, L | Min. pump power, L/min | Weight, kg |

KHL120 | 120 | 45 | 150 | 400 | 50 | 595 |

KHL160 | 160 | 45 | 250 | 550 | 50 | 685 |

KHL200 | 200 | 45 | 250 | 750 | 50 | 765 |

FMG mechanical open sweeping machines are designed for forward movement, but the AH380 model can alternatively be ordered for reverse operation. Mechanical open-type sweepers are ideal for sweeping sand, dust, leaves, and snow.

Mechanical sweeping machines operate from a front or rear PTO. This way, the brush does not require much hydraulics, making it more economical. All mechanical open-type sweepers can be mounted on the rear hitch of a tractor, while the AH380MEK is also suitable for front mounting.

Mechanical sweeping machines are equipped with a floating mounting frame, which accurately follows the road surface to achieve the bescleaning results. The maximum brush rotation angle is 28 degrees to either side, and the rotation is hydraulically controlled.

Model | Width, cm | Height, cm | Working width, cm | Brush diameter, cm | Weight, kg | PTO, rpm |

AH260MEK | 285 | 115 | 260 | 70 | 560 | 540 |

AH300MEK | 315 | 115 | 300 | 70 | 650 | 540 |

AH380MEK | 410 | 115 | 380 | 90 | 1400 | 1000 |

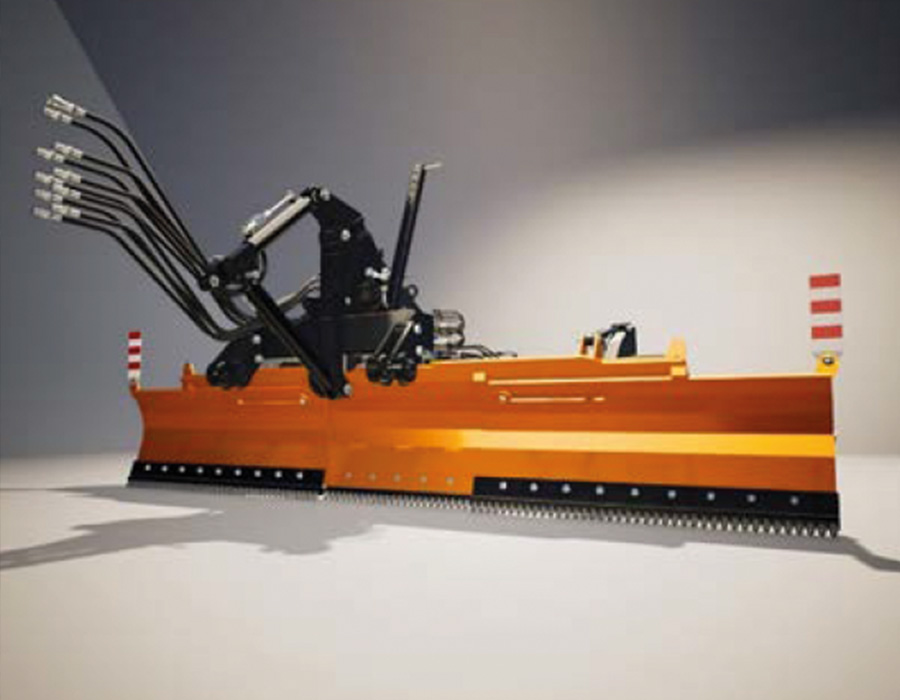

FMG tractor grader blades are designed for professional use to remove ice and snow in winter and to level dirt and gravel roads in summer. To ensure good surface traction, FMG scraper blades are equipped with a patented hydraulic pressure regulator, which allows the tractor’s weight to be transferred onto the blade. When fitted with a cutting edge, the graders can even replace larger road maintenance equipment.

The grader blades are mounted on a tractor’s 3-point hitch, making them easy to use. Adjustable balancing wheels maintain a consistentworking depth, while hydraulic pressure control reduces vibration.

FMG grader blades are available in the following variations: straight blade (standard), perforated blade* , and cutting edge* . Extendable wings* and cylinders for lower-level adjustment* are also available as optional equipment.

Model | Width, cm | Height, cm | Extension wing, cm | Working width, cm | Turning angle | Weight, kg |

RAP245 | 245 | 60 | 30 | 215-245 (305*) | 28° |

|

RAP275 | 275 | 60 | 30 | 245-275 (335*) | 28° | 650 |

RAP300 | 300 | 60 | 30 | 270-300 (360*) | 28° | 680 |

The new FMG HD-Scraper is equipped with a removable hydraulic pressure cylinder, making it easier to connect the HD-Scraper. The standard 3- meter blade already provides plenty of capabilities, but additional hydraulic extensions give you extra working width and new operational possibilities. As standard equipment, you get swivel support wheels (290 mm wide), a cutting edge, pressure relief couplings for hoses with a manifold, a toolbox with spare pins and tools for replacing the cutting edge pins, as well as batteries. Optional hydraulic drive support wheels are also available.

NOTE: Support wheels shown in the images may differ from the wheels delivered to the customer.

Equipment

Standard: 3 m main blade, cutting edge, swivel support wheels, hydraulic top link, hydraulic pressure cylinder, hydraulic tilt (2 cylinders) (+/- 27 degrees), pressure relief sockets for hoses, toolbox, tools for replacing cutting edge pins.

Options: Hydraulic extendable wings (left or right), hydraulic support wheels (left or right), 6/2 electric valve with external coupling and electric control.

Model | Width, cm | Height, cm | Extension wing, cm | Working width, cm | Turning angle | Weight, kg |

RAP300HD | 304 | 64 | 45 | 270 – 300 (without extensions) | 27° | 1200 (without extensions) |

FMG pull-type graders are an excellent and cost-effective solution for maintaining dirt and gravel roads. FMG graders can be towed by medium andlarge agricultural tractors. Hydraulic control provides all necessary adjustments, such as leveling the road at right angles, raising and lowering the blade, and shaping the road edges to direct water into ditches. The balancing bar helps maintain optimal settings. A hydraulically driven finishing blade is available as an option. All FMG tractor-pulled graders are equipped with a wheel roller that instantly compacts the surface, preventing material from drying out.

The FMG tractor-pulled grader range consists of four models for roads and tractors of different sizes. The smallest model, TLN250, is ideal for roads3–4.5 m wide. TLN370 is suitable for roads 3.5–5 m wide, TLN430 for roads 5–6 m wide, and TLN570 for roads up to 7 m wide. The recommendedminimum tractor power is 120 hp, and the recommended weight ranges from 5,000 kg to 8,000 kg depending on the grader model and desired working depth. It is important that the grader size matches the road to achieve optimal leveling. A properly shaped road profile helps prevent damage, for example, after heavy rain.

Model | Working width, cm | Working width with extendable width, cm | Length, cm | Blades | Weight, kg | Connection |

250 TLN | 250 | 290 | 670 | 4 | 2700 | Hitch |

370 TLN | 275 | 310 | 855 | 4 | 3750 | Hitch |

430 TLN | 310 | 350 | 890 | 4 | 4420 | Hitch |

570 TLN | 350 | 370 | 940 | 4 | 5800 | Hitch |

The suspended grader is a cost-effective road maintenance system that is always ready for use.

The suspended grader does not interfere with other work equipment and allows the use of the front hitch, drawbar, or front loader. All tractor hydraulic blocks remain available for use with other attachments.

The underbody scraper, positioned in the center of the tractor, provides stable operation. The combined weight and force of the tractor can be applied directly to the underbody scraper.

The underbody scraper offers a large working width while maintaining a compact transport width. During transport, it is practically unnoticeable. The underbody scraper does not affect visibility compared to other equipment.

FMG 3D BLADE CONTROL Height, tilt, and blade rotation adjustment provide extensive possibilities for road shaping. |

MULTISLIDER EXTENSION WINGS Unique design of the extension wing. |

UNIQUE DESIGN The FMG Sensor Blade system has no external vertical cylinders, reducing the risk of malfunction. The blade geometry ensures smooth matflow. The turning angle is symmetrical on both sides, with a precise hydraulically adjustable turning angle of +/- 25°. |

CENTRALIZED LUBRICATION SYSTEM The centralized lubrication system is included as standard equipment. It simplifies lubrication and saves time during maintenance. |

HIGH GROUND CLEARANCE Ground clearance is 260 mm in transport position and 150 mm in working position (T4 Stage 4, Nokian Ground King 42"). |

TOOTHED BLADE The toothed blade is included as standard equipment. This type is ideal for maintaining gravel roads in summer and removing ice in winter. |

| STANDARD EQUIPMENT | OPTIONAL EQUIPMENT |

|

|

Model | АТ-СБ |

Transport width | 2480 mm |

Working width | 2256 mm – 3376 mm |

Working width at maximum turning angle | 2256 mm – 3093 mm |

Turning angle | +/- 25° |

Side tilt | +/-5° |

Weight | 1055 kg |

Blade height | 416 mm |

Dimensions of the extension / side (additional working width) | 450 mm |

Dimensions of the extension / side (additional working width at turning angle) | 419 mm |

Ground clearance in working position (T4 stg4, Nokian Ground King 42″) | 150 mm |

FMG ST multifunctional tractor multi-lift trailers are designed to replace several standard trailers on your farm or for contractor use. This saves money, as only one trailer is needed to perform multiple tasks. FMG ST tractor multi-lift trailers can be equipped with EBS anti-lock brakes and technology allowing a maximum speed of up to 60 km/h.

FMG ST tractor multi-lift trailers are used by the Finnish Defence Forces, and collaboration with this special customer has ensured additional reliability and new features for civilian trailer versions as well. Automatic container switching, load scales, and independent hydraulic suspension on each wheel are just a few examples of useful standard features.

The unique sliding hook design provides a very low container lift angle and sufficient force to handle fully loaded heavy containers.

Model | ST16 | ST18 |

Lifting capacity, t | 16 | 18 |

Width, m | 2,55 | 2,55 |

Container length, m | 4-6 | 4-6 |

Weight, kg | 4500 | 4700 |

Lifting cylinders, mm / quantity | 125/2 | 145/2 |

Max. tilt angle, ° | 55 | 55 |

Min. hook height, m | 1,2 | 1,3 |

Max. oil consumption for tipping, L | 10 | 10 |

Standard tires | 550/60-22,5 | 550/60-22,5 |

Max. tires | 710/45-22,5 | 710/45-22,5 |

Wheelbase, m | 1,36 | 1,36 |

Front wheel brakes (hydraulic) | Standard | Standard |

4-wheel brakes (hydraulic) | Optional | Optional |

EBS anti-lock brakes with compressed air | Optional | Optional |

Automatic container change | Standard | Standard |

| Hydraulic tailgate | Standard | Standard |

Hydraulic suspension on 4 wheels | Standard | Standard |

Mudguards on 4 wheels | Optional | Optional |

Rear LED lights | Standard | Standard |

Additional lighting kit (oblique + daytime running lights) | Optional | Optional |

Toolbox | Optional | Optional |

Ball coupling on drawbar | Optional | Optional |

ALB brakes (load-sensitive automatic) | Standard | Standard |

Automatic container lock | Standard | Standard |